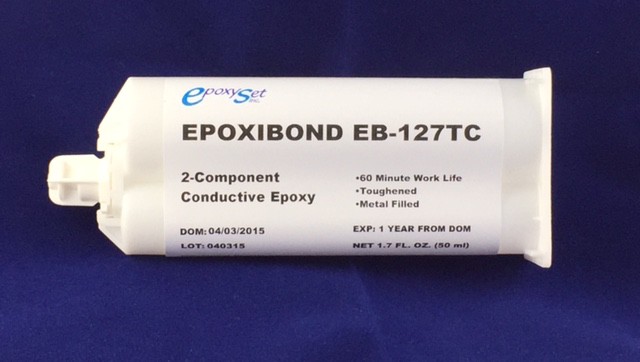

EB-127TC

Is aluminum filled epoxy conductive?

EB-127TC

Introducing thermal conductivity to epoxies is a matter of price and practicality. Generally, the highest thermally conductive materials are also very expensive. For example, silver filled adhesives can costs upwards of $1000.00/lb. Aluminum not only adds thermal conductivity to epoxy systems but also structural integrity. Aluminum is also an affordable material compared to others. EB-127TC is a thermally conductive 2-part epoxy using aluminum metal fillers for good thermal conductivity. Applications include low cost thermal relays in heat sensors and to pull heat away from high powered LEDs.

Using newly engineered toughening agents for consistent distribution and highly conductive aluminum filler, EB-127TC is excellent for LED applications as a thermal interface materials. Available in easy to use dual cartridges, EB-127TC is ideal for high output manufacturing.

Product Specifications

| No.of Components | 2 |

| Mix Ratio by Weight | 100/50 |

| Mixed Viscosity @RT(cps) | 100,000 - 120,000 |

| Pot Life @25°C(100 gram) | 60-80 min |

| Recommended Cure | 24 hrs @ 25°C |

| Alternate Cure | 2 hr @ 70°C |

| Color | Grey |

| Specific Gravity | 1.6 |

| Hardness(Shore) | D-86 |

| Refractive Index | |

| Lap Shear Strength @25°C(psi) | 3500 |

| Tg(°C) | 62 |

| CTE(Below Tg)10-6/°C | 55 |

| Service Temp.Range | -55°C to 160°C |

| Thermal Conductivity(W/m°K) | 0.9 |

| Volume Resistivity(500 V) | 3.0 x 10^15 |

Recommended Applications

Use the form below to request additional information & product data