Electrically Conductive Epoxy Adhesives

Silver filled epoxy adhesives are the most used epoxy systems when conductivity is required. The specialty silver flakes and powders used to product our epoxies give the systems super high conductivity and low resistance for the life of the part. Silver, unlike copper and graphite, does not oxidize which allows it to keep its conductivity and resistance for years. You may say to yourself, gold also has these same qualities. It is true that gold it is highly conductive and doesn’t oxidize, but the cost makes it almost prohibitive. With conductive epoxies and silicones, there is nothing like silver.

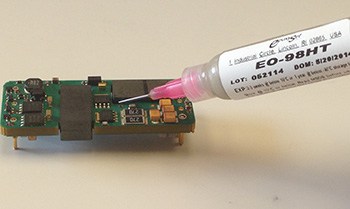

One and two component, silver filled, electrically conductive compounds feature low volume resistivity and high reliability. They offer excellent physical strength properties, superior substrate adhesion and uniform electrical conductivity. They are often used as replacements for solder.