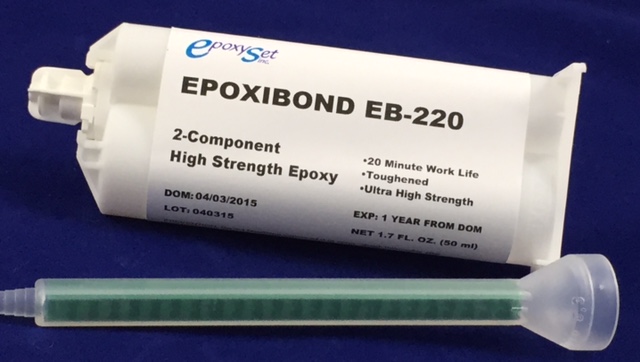

EB-220

Do all metals bond the same?

EB-220

Metals are generally easier to bond compared to rubbers, plastics, and ceramics. However, some metals are easier to bond than others. Metals such as aluminum and steel are easier to bond than metal alloys or anodized aluminum. Anodized aluminum is a treated aluminum which results in a thick aluminum oxide layer, porous surface, and a more brittle metal. This thick oxide can reduce the strength of epoxy by more than 50%. While high porosity can be useful in bonding, anodized aluminum is usually sealed reducing the pore sizes. To compensate for this, special abrasion or chemical treatments can be performed to make the substrate viable.

EB-220 is a quick setting, toughened epoxy adhesive system with excellent adhesion to aluminum, steel, copper, and alloys. When metal surfaces are prepared/treated properly, EB-220 can create an extremely high bond strength.

Product Specifications

| No.of Components | 2 |

| Mix Ratio by Weight | 100/50 |

| Mixed Viscosity @RT(cps) | 30,000 - 40,000 |

| Pot Life @25°C(100 gram) | 20 min (20 g) |

| Recommended Cure | 8-10 hrs @ 25°C |

| Alternate Cure | 24-48 hrs @ 25°C |

| Color | Black/White |

| Specific Gravity | 1.14 |

| Hardness(Shore) | D-77 |

| Refractive Index | |

| Lap Shear Strength @25°C(psi) | 4500 |

| Tg(°C) | 60 |

| CTE(Below Tg)10-6/°C | 130 |

| Service Temp.Range | -55°C to 120°C |

| Thermal Conductivity(W/m°K) | 0.1 |

| Volume Resistivity(500 V) | >10^15 |

Recommended Applications

Use the form below to request additional information & product data