Encapsulation of chips and modules on PCBs, smart cards, and flex circuits are increasingly prevalent in the ever growing digital and hands-free world. The global smart card market had a value of $10.19 in 2019 and is expected to grow to over $15 billion by 2027. Smart cards are becoming increasingly popular due to its enhanced speed and security. Smart card usage ranges from credit cards, gift cards, government and corporate identification and transit fare cards.

Traditional encapsulation materials such as one-component heat cure epoxies have been used significantly. They are strong, resilient against everyday usage, resistant to solder reflow, and are rheologically formulated for easy dispensing. Historically they have also been considered “fast cure” as some can be cured in as little as 10 minutes. With the evolution of new technologies, light cure encapsulating materials for smart cards technology has been able to increase the output and efficiency of manufacturers.

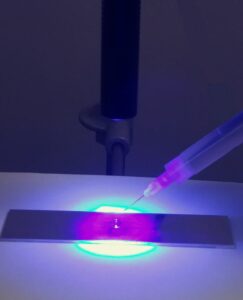

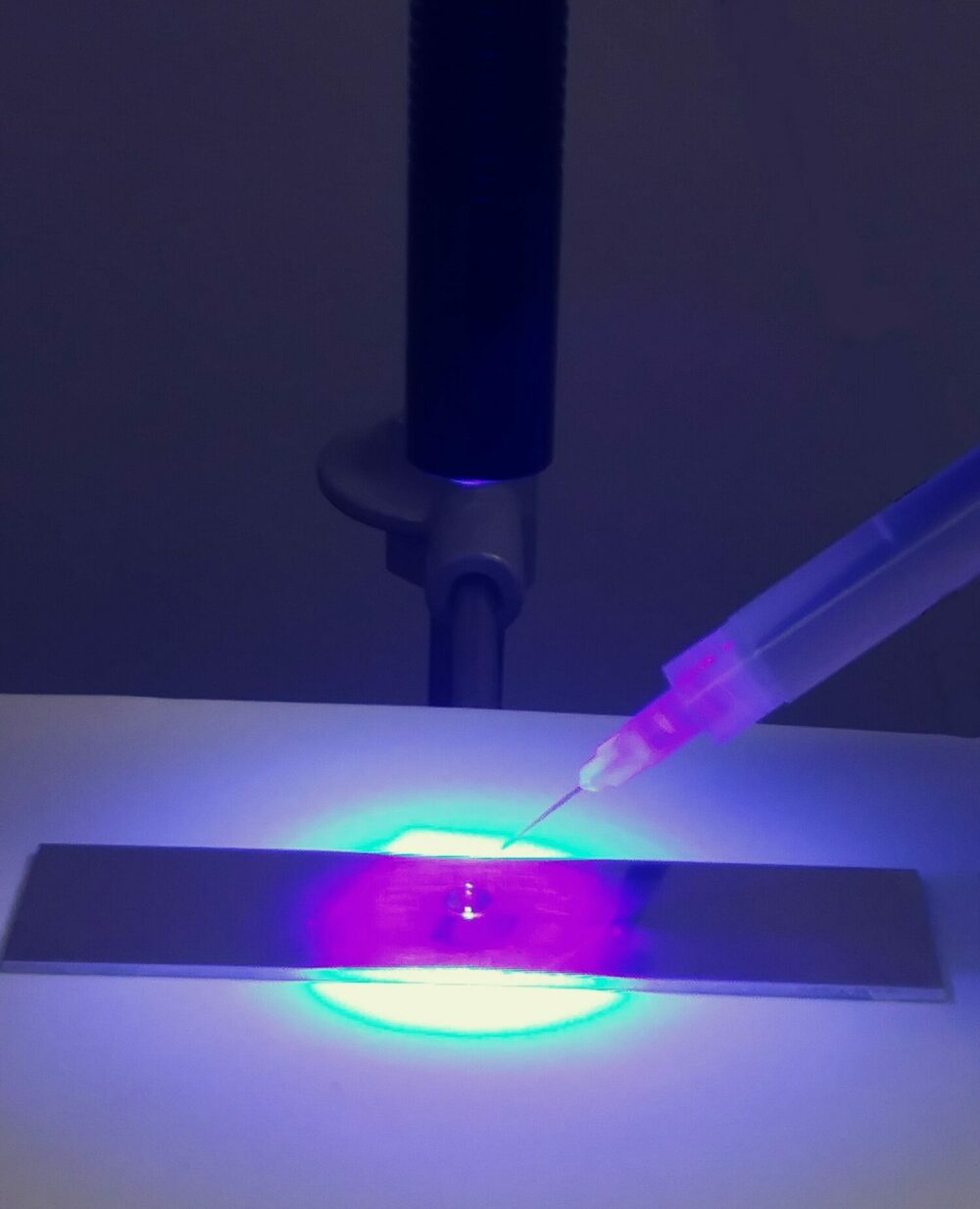

Epoxyset, in addition to traditional one part, heat cure epoxies, offers light cure encapsulating materials for smart cards technology.

UV-5400LV – a low viscosity, low CTE adhesive for fill operation that will offer high strength to all PCB materials.

UV-8300T – a thixotropic, damming material with very low CTE.

All these advanced polymers are low ion /high purity and halogen free as well as REACH & RoHS compliant. They are all specifically formulated to cure in 10 seconds with a bond line intensity of 250mW/cm2, 365nm LED energy source. Of course, they will cure just as quickly with D or H style UV lights. They can also be gelled at lower intensities and then heat post cured for manufacturing flexibility. These systems pass 1000 hours at 85%RH/85°C and offer continuous operation at 150°C.

See our article on electronic packaging products at US Tech Online