Flip chip die attach is a technique used in the semiconductor and microelectronics industry for connecting semiconductor chips (known as dies) directly to substrates or carrier packages. In this method, the chip is flipped over and attached facedown onto the substrate or carrier using a conductive adhesive material. This is in contrast to the traditional wire bonding method, where the connections are made by bonding wires from the chip to the substrate.

The process of flip chip die attach typically involves the following steps:

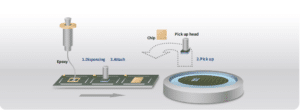

1. Preparation: The substrate or carrier is prepared with the necessary connections and bonding sites, often using under bump metallization (UBM) or other connection methods.

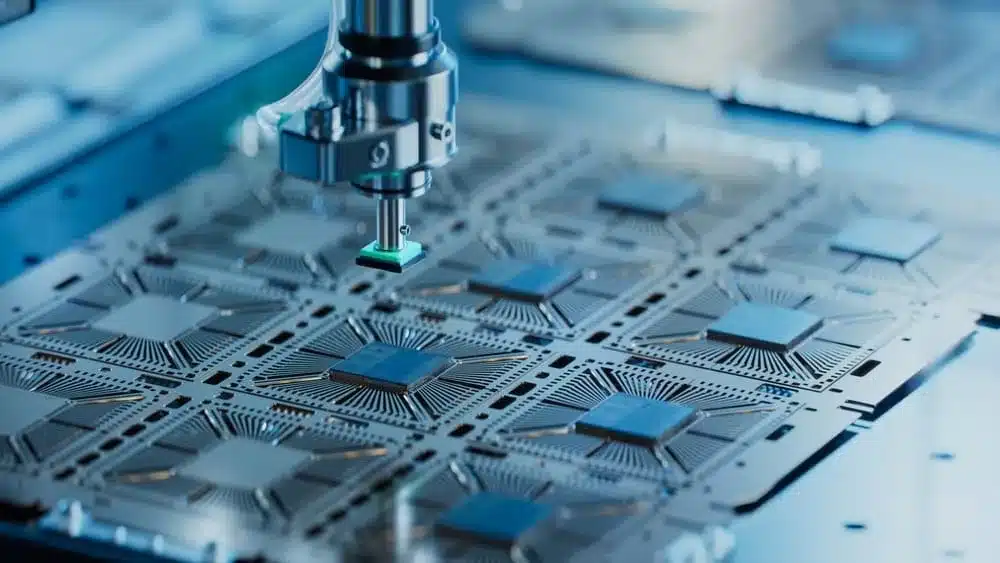

2. Application of Adhesive: A conductive adhesive, often a silver-filled epoxy or other electrically conductive material, is applied to the connections on the substrate or the chip.

3. Alignment and Placement: The chip is “flipped” and precisely aligned with the bonding sites on the substrate. This can be achieved through automated machinery and vision systems.

4. Bonding: Once aligned, pressure and sometimes heat are applied to the chip, allowing the conductive adhesive to bond the connections between the chip and the substrate.

5. Curing: The adhesive is cured or solidified, securing the chip in place and creating the necessary electrical connections between the chip and the substrate.

This method offers several advantages:

- Improved Performance: Flip chip connections typically offer better electrical and thermal performance compared to wire bonding due to the shorter interconnection paths and reduced inductance.

- Higher Density: This method allows for higher interconnect density on the substrate, as it eliminates the need for wire bonding and allows more connections in a given area.

- Enhanced Reliability: The connections made using flip chip die attach often have improved mechanical strength, making them more reliable in various operating conditions.

- Thermal Management: The direct connection facilitates better heat dissipation, which is crucial in many semiconductor applications.

Flip chip die attach is commonly used in various electronic devices, including microprocessors, memory chips, image sensors, and other high-performance integrated circuits where high-density interconnects, improved performance, and reliability are essential. The choice of the die attach material, such as conductive adhesives like silver-filled epoxies, plays a crucial role in the success and durability of the flip chip bonding process.