Silver-filled epoxies are a type of electrically conductive adhesive that contains silver particles or flakes as a filler material within an epoxy resin matrix. These adhesives are designed to provide both electrical conductivity and strong mechanical bonding properties. They are commonly used in various applications, particularly in electronics and microelectronics, where a reliable and electrically conductive bond is required.

Electrical conductivity of an adhesive is typically measured by its volume resistivity. The volume resistivity of a polymer material is its ability to oppose the flow of electric current through a volume of the cubic specimen. The SI unit of volume resistivity is ohm-meter (Ohm-m).

Volume resistivity is also known as:

- electrical resistivity,

- bulk resistivity,

- specific electrical resistance, or

- specific volume resistance.

Here are some key characteristics and applications of silver-filled epoxies:

1. Electrical Conductivity: The silver particles in these epoxies act as conductive pathways, allowing for the transmission of electrical current. This makes them useful in applications where electrical connections or grounding is essential.

2. Bonding Strength: Silver-filled, electrically conductive adhesive typically offer strong adhesive properties, creating reliable bonds between components. They can be used to bond various materials, including metals, ceramics, FR4, and some plastics.

3. Thermal Conductivity: Silver is also a good thermal conductor, so silver-filled epoxies can help dissipate heat in applications where thermal management is important, such as in semiconductor devices.

4. EMI/RFI Shielding: These epoxies can be used to create electrically conductive seals or coatings for electromagnetic interference (EMI) and radio-frequency interference (RFI) shielding in electronic devices and enclosures.

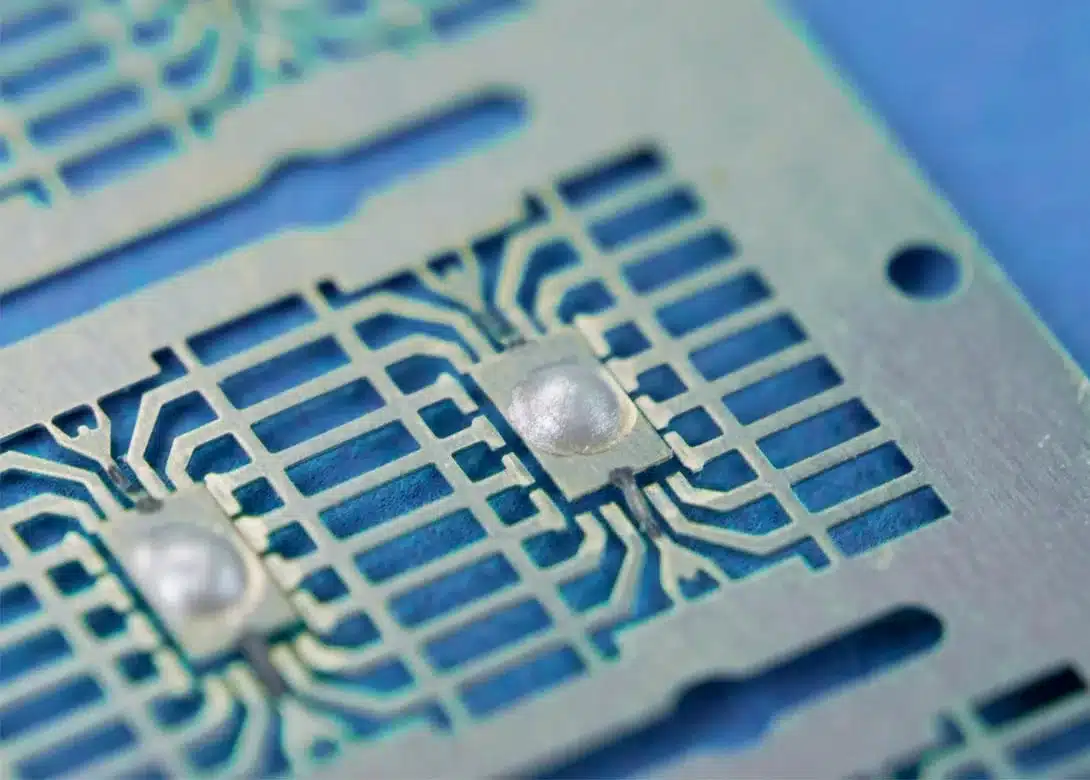

5. Die Attach: Silver-filled epoxies are commonly used in the microelectronics industry for die attach applications, where they bond semiconductor chips (dies) to substrates or lead frames. This ensures good electrical and thermal connections.

6. Circuit Repairs: An electrically conductive adhesive can also be used for repairing and reworking electronic circuits, especially in situations where soldering is not feasible or preferred.

7. Flexibility and Cure Time: The properties of silver-filled epoxies can vary, with options available for different levels of flexibility and cure times to suit specific applications.

8. Environmental Considerations: Some electrically conductive adhesives may contain volatile organic compounds (VOCs) or other materials of environmental concern. Be sure to check the product specifications and adhere to proper handling and disposal guidelines.

When using silver-filled epoxies, it’s essential to follow the instructions regarding application methods, curing processes, and recommended substrates to achieve optimal performance. Additionally, compatibility with the specific materials and environmental conditions of your application should be carefully considered.