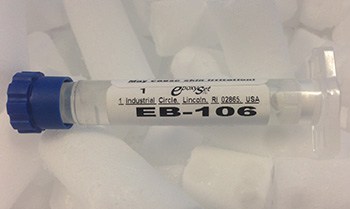

EB-106

Can epoxy withstand medical sterilization?

EB-106

Medical devices are subject to very rigorous sterilization processes. Epoxies used in manufacturing these medical devices must be able to withstand sterilization repeatedly. Not all adhesives can withstand the sterilization process which is why a product like EB-106 is used so highly used. Conditions can be extremely harsh during sterilization and the epoxy is exposed to harsh temperatures, chemicals, steam, and heat.

EB-106 has been used for over 15 years in medical device manufacturing by some of the world’s largest device manufacturers. It is a 1-part, low viscosity, unfilled epoxy system. EB-106 is only available as premixed and frozen syringes in a variety of sizes ranging from 1cc to 6oz cartridges. It is also a very versatile epoxy and can be used an adhesive, encapsulant, sealant, and coating. Room temperature curable, EB-106 exhibits high strengths to metals, rubbers, ceramics, and glass. Applications include potting small electronic components, as a matching and backing layer in ultrasound transducers, and laminating PZT to ceramics.

Product Specifications

| No.of Components | 1 |

| Mix Ratio by Weight | |

| Mixed Viscosity @RT(cps) | 300-500 |

| Pot Life @25°C(100 gram) | 60 min |

| Recommended Cure | 3 hrs @ 65°C |

| Alternate Cure | 24-48 hrs @ 25°C |

| Color | Clear |

| Specific Gravity | 1.16 |

| Hardness(Shore) | D-85 |

| Refractive Index | 1.52 |

| Lap Shear Strength @25°C(psi) | 2700 |

| Tg(°C) | 65 |

| CTE(Below Tg)10-6/°C | 59 |

| Service Temp.Range | -55°C to 125°C |

| Thermal Conductivity(W/m°K) | NA |

| Volume Resistivity(500 V) | >10^14 |

Recommended Applications

Use the form below to request additional information & product data