EO-23M

Gold vs Silver filled epoxy

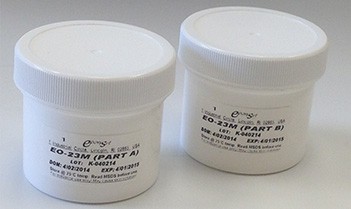

EO-23M

Why is silver filled epoxy preferred over gold? Gold presents several issues such as cost, variety, and demand. Gold filled epoxy is over 20 times more expensive than standard silver filled epoxies at over $85/gram. For many applications using gold filled epoxy may be intriguing and possibly useful but the price eliminates the option. Next is the variety of silver filled systems. Epoxyset offers a variety of silver filled epoxies with different viscosities, work lives, and cured properties. Gold filled epoxies all tend to be high viscosity, paste products due to its high oil absorbency and lack of particle size distribution. Finally, the demand for the properties of gold filled epoxy is very low. Only very specialized applications call for them and will not work without the use it.

EO-23M is highly filled, thermally and electrically conductive epoxy adhesive that can cure at room temperature and is used in aerospace, electronics, and medical applications. In aerospace guidance systems where there are high performance standards, EO-23M is used for EMI and Rf shielding to prevent electronic malfunction. EO-23M is used in the electronics of automotive applications for pressure sensing and accelerometer components. It is also an eelectrically conductive adhesive (ECA) for connections of circuits to Cu coils in Rf antenna applications such as smart cards and RFID tags.

Product Specifications

| No.of Components | 2 |

| Mix Ratio by Weight | 100/4 |

| Mixed Viscosity @RT(cps) | 5000 |

| Pot Life @25°C(100 gram) | 1 hr |

| Recommended Cure | 2 hrs @ 80°C |

| Alternate Cure | 24-48 hrs @ 25°C |

| Color | Silver |

| Specific Gravity | 2.90 |

| Hardness(Shore) | D-84 |

| Refractive Index | NA |

| Lap Shear Strength @25°C(psi) | 1700 |

| Tg(°C) | 68 |

| CTE(Below Tg)10-6/°C | 62 |

| Service Temp.Range | -55°C to 150°C |

| Thermal Conductivity(W/m°K) | 2.0 |

| Volume Resistivity(500 V) | 0.0008 |

Recommended Applications

Use the form below to request additional information & product data