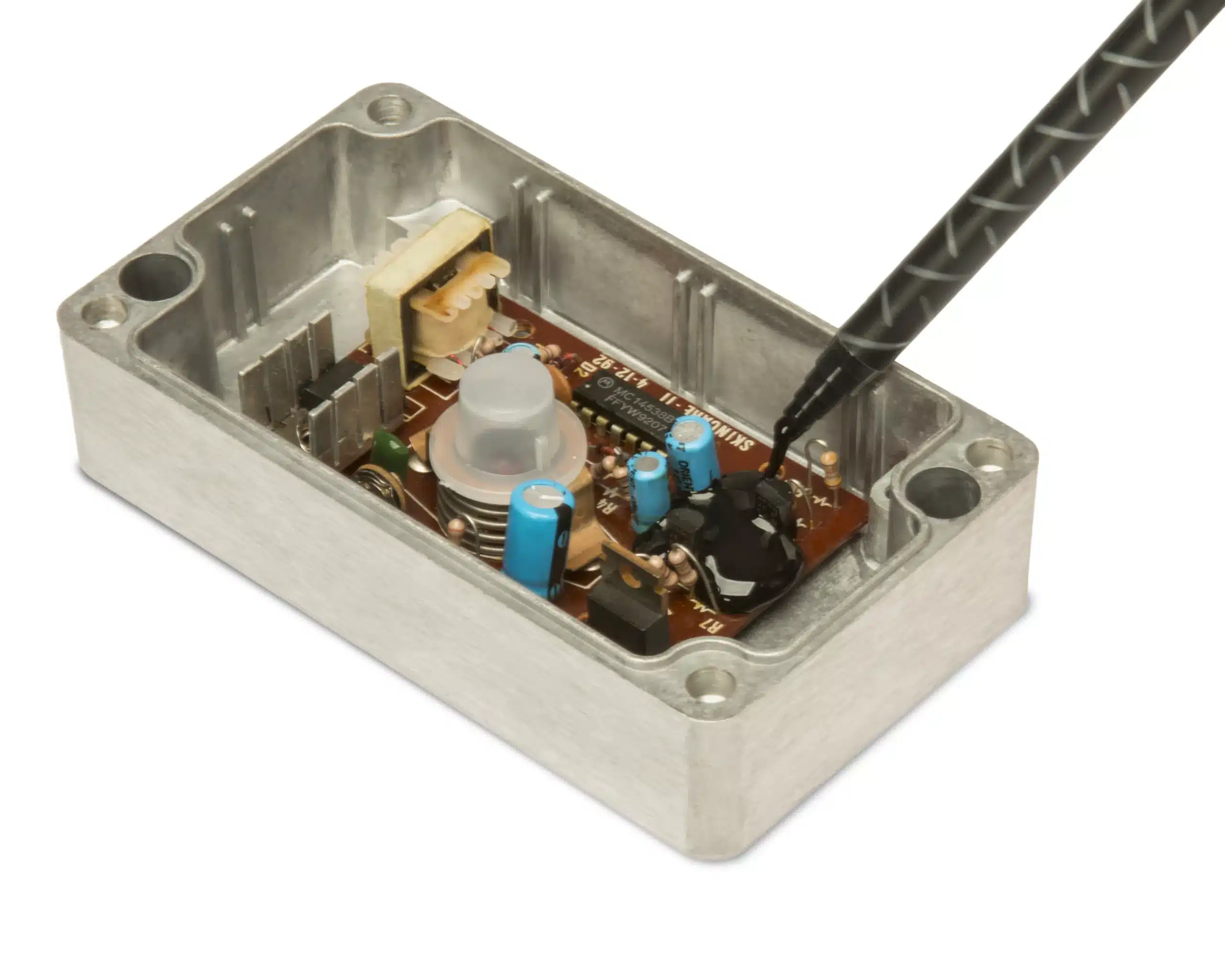

In today’s market, electronic components are subjected to some pretty brutal environments that can drastically diminish the working life of electronic devices. However, manufacturers can take steps to reduce environmental and mechanical exposures by utilizing potting compound and encapsulation methods. Advancements in materials science have led to innovative solutions to protect sensitive electronic components from damage and prolong their life. Electronic potting uses these state-of-the-art materials to create a protective casing, resulting in many benefits.

Electronic potting compounds are highly specialized for unique applications, and using the wrong compound can negate the benefits of potting components. However, the correct product, properly applied, can extend the life of the device by providing improved stability and protection from environmental stressors. These compounds are specially formulated to provide unique characteristics, such as high-temperature resistance, thermal and electrical conductivity, and elastomeric properties.

![]()

Considerations for Choosing the Right Compound

Because no two potting compounds are the same, choosing the right one for your application can be challenging. When considering your options, it’s essential to have a thorough understanding of the expected and potential stresses that will be placed on the device and its internal components.

Environmental Stressors

The primary consideration when choosing electronic potting compounds is the electronic device’s operating environment. Urethane-based potting compounds, for example, are more likely to degrade when exposed to high temperatures and ultimately fail but are ideal for outdoor applications. Silicone-based potting compounds, on the other hand, tend to perform extremely well in high-temperature settings but will swell with exposed moisture. As such, it’s critical to choose a potting compound that is formulated to withstand your application’s environmental factors, including service temperature, moisture, chemical exposure, and vibrations.

Application Requirements

Component size and volume requirements also play an important role in determining the best potting compound. For tiny components and low-volume needs, an electronic adhesive may be more cost-effective than specialized potting compounds. Other aspects, such as viscosity and pot life, also come into play when considering application requirements. A low-viscosity compound is more fluid and will flow more easily into tight spaces, but it can seep into unexpected areas if the application isn’t precise. In contrast, a high-viscosity products will maintain its shape but might trap air bubbles next to sensitive components unless additional degassing is administered. Pot life refers to how long the compound is workable before it begins to gel, in the case of room temperature curing compounds, it hardens and becomes unworkable. The shorter the pot life, the less time to work with the mixture.

Hardness and Elasticity

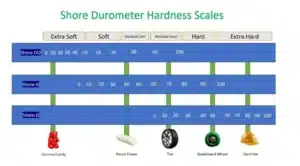

Hardness is a major characteristic of electronic potting compounds, and not every device requires potting with the same level of elasticity. The hardness of potting compounds is measured on the Shore Scale.

Softer, more elastic compounds, such as some silicone-based potting compounds, can provide greater elasticity, protecting fragile components and making them more easily accessible for maintenance and repair. Harder potting compounds, on the other hand, create permanent hermetic seals around components, preventing the ingress of moisture and other contaminants.

Refractive Index

When electronics use optical components, the potting compound’s refractive index is sometimes crucial. Most compounds will block light from reaching the internal components to protect them from UV damage. However, optical potting compounds can be specially formulated to allow light to pass through.

Lap Shear Strength

To prevent components from becoming dislodged due in higher stress applications, the potting compound requires a higher lap shear strength to maintain their bond integrity. However, not all applications require high lap shear strength, such as in stationary devices.

Types of Electronic Potting Compound

Electronic potting compounds can be broken down into three general categories based on their chemistry. Each type of compound has its own unique properties. Regardless of the base chemistry, electronic potting compounds are available in a wide range of highly specialized formulas, including flame retardant, thermally conductive, and high-temperature formulas.

Epoxy

Epoxy-based potting compounds are generally rated higher on the Shore Hardness Scale, providing rigid protection for delicate components. They have excellent dielectric properties, making them well-suited for use in electronic device manufacturing. Due to their high tensile strength, they offer durable protection and structural support. When applied correctly, they form an airtight seal that protects against chemical contamination. Epoxies have thermal conductivity properties that allow them to dissipate heat, thus protecting components. However, many are not suited for applications with consistent temperature cycling.

Urethane

Urethane compounds are generally more flexible once cured than epoxy-based formulas. Their elastomeric properties allow them to withstand exposure to extremely low temperatures. However they will degrade quicker in high-temperature applications. Depending on the formulation, urethane potting compounds provide superior protection against moisture ingress, making them ideal for electronic devices with outdoor applications.

Silicone

Silicone potting compounds have even greater elastomeric properties. They are generally softer once cured, with a rubbery texture, making them a good option for low-stress environments. They are particularly suitable for high-temperature and temperature cycling applications. However, silicone potting compounds are much more costly than epoxy or urethane-based formulas and have a tendency to swell when exposed to high moisture environments.

Application Tips for Optimal Results

Regardless of the type of electronic potting compound, proper application is vital to achieve the desired component protections. In order for a potting compound to form a hermetic seal, components and substrates must be cleaned, and steps should be taken to prevent any air inclusions. It’s also important to properly store compounds to ensure they retain their desired properties. Premixed and frozen syringes, for example, must be stored at or below -40 degrees and undergo thawing before use. Most urethane products must be kept dry and sometimes require a dry nitrogen blanket.

For more information, please contact the experts at Epoxyset today!