Cationic epoxy, more commonly UV cure epoxy, refers to a type of epoxy resin system that cures through a cationic (positively charged) polymerization mechanism. Epoxy resins are polymers widely used in various industrial applications, including adhesives, coatings, and composites, due to their excellent adhesive properties, chemical resistance, and mechanical strength.

In a cationic epoxy system, the curing process involves the reaction of epoxy groups (usually present in the resin) with a cationic initiator, which typically contains onium salts such as diazonium, sulfonium, or iodonium salts. When these initiators are exposed to specific wavelengths of light (UV light for example) or heat, they dissociate into cationic species. These cationic species then react with the epoxy groups, leading to the formation of cross-linked polymer networks.

The key characteristics and advantages of cationic epoxy systems include:

- Low shrinkage: Cationic epoxy systems often exhibit low shrinkage during curing, which can be advantageous in applications where dimensional stability is critical.

- Good adhesion: They typically offer excellent adhesion to a wide range of substrates including metals, plastics, and ceramics.

- Chemical resistance: Cationic epoxy coatings tend to have good resistance to chemicals, making them suitable for use in harsh environments.

- High-temperature resistance: The cross-linked polymer networks formed during curing provide good thermal stability, making cationic epoxy systems suitable for high-temperature applications.

- Moisture resistance: Once cured, cationic epoxy coatings generally exhibit good resistance to moisture and humidity.

- UV curable: Some cationic epoxy systems can be cured using UV light, offering fast curing times and energy efficiency.

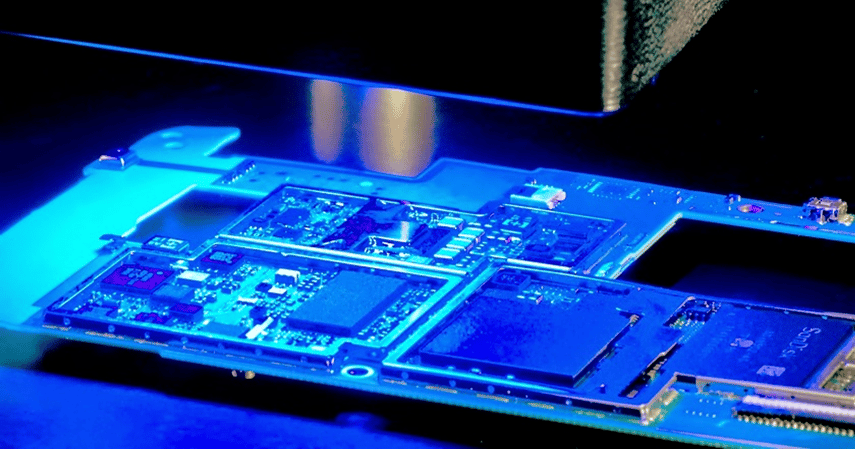

UV cure epoxy systems find applications in various industries such as electronics, automotive, aerospace, and marine coatings, where their unique properties are utilized to provide durable and high-performance coatings, adhesives, and encapsulants. However, it’s worth noting that proper handling and curing conditions are essential to achieve the desired performance characteristics.